In recent years, we’ve seen a surge of news related to achieving a sustainable society: the rethinking of plastic straw usage, and the growing attention on products made from eco-friendly materials. One major driving force behind this is the United Nations’ Sustainable Development Goals (SDGs), a set of global objectives to be achieved by 2030.

To realize a truly sustainable society, shouldn’t we consider what each of us can do? The item we want to propose today is something deeply rooted in Japanese life: disposable wooden chopsticks “Waribashi.” “Is Waribashi eco-friendly? Are they sustainable?” If those thoughts crossed your mind, then this is a must-read!

Born from the Spirit of “Mottainai” — History of “Yoshino Waribashi”

The birthplace of disposable wooden chopsticks is said to be Shimoichi Town in the Yoshino region of Nara Prefecture, western Japan.

By the Nara period (710–794 AD), chopsticks were already in common use across Japan. Later, during the Nanbokuchō period (14th century), it’s said that local villagers in Shimoichi presented cedar chopsticks to Emperor Go-Daigo, who resided at the Imperial Palace in Yoshino region. The emperor was delighted by their elegant grain and aromatic scent of the wood that he used in the morning and evening. This royal endorsement quickly led to the chopsticks being adopted by court nobles and Buddhist monks, cementing their place in Japanese culture.

The story of “Yoshino Waribashi” begins in the Edo Period (1603–1868), born from a desire not to waste the residual wood from the production of tarumaru, the curved staves with Yoshino Cedar used for making sake barrels.

Yoshino Cedar was highly prized and used for sake barrels because its fine, straight grain and few knots made it remarkably leak-resistant. Furthermore, sake brewed in Kamigata, around Kyoto and Osaka which was the cultural center of Japan back then, was often shipped to Edo, present-day Tokyo, in these Yoshino Cedar barrels. During the journey by boat, the sake would absorb a faint, subtle elegant scent from the cedar, delighting the people of Edo.

This culture of sake barrel craftsmanship was instrumental in the development of the local forestry, leading to the rise of Yoshino Forestry as “Tarumaru Forestry”, barrel-stave forestry.

In the Meiji period (1868–1912), a local teacher named Tadao Shimamoto from Shimoichi designed a new “matsuba-gata” (pine-needle-shaped) chopstick—two sticks joined as one pair.

This design is regarded as the origin of the modern disposable chopstick. After being commercialized, it was distributed nationwide by chopstick merchants from Tokyo.

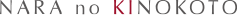

Today, “Yoshino Waribashi” are still produced mainly in Shimoichi and neighboring Yoshino Town. These chopsticks are crafted exclusively from the outermost, otherwise unusable remnants and offcuts of Yoshino Cedar and Yoshino Cypress logs from forest thinning processes instead of barrel staves.

Crucially, no trees are harvested solely for the purpose of making these chopsticks but only the scraps are what remains after the trees have been milled for architectural lumber.

Even sawdust produced during manufacturing is recycled into insulation, wallpaper, planting mats, or even bath additives. Used chopsticks also can be repurposed as biomass fuel or paper pulp, ensuring that nothing goes to waste.

In short, “Yoshino Waribashi” embodies Japan’s timeless “Mottainai” spirit—turning “what’s left over” into something of new value.

Sawdust left from the chopstick-making process

Fine-Grained, Beautiful, and Strong — What Makes Yoshino Wood Special

When you hear that “Yoshino Waribashi” are made from the remnants of lumber from forest thinning process, you might wonder: “Are they using thin or poor-quality wood?” The answer lies in the unique practice of Yoshino Forestry.

In Yoshino Forestry, trees are planted in high density. This intentional closeness prevents the trunks from growing too wide, producing straight timber with a remarkably uniform thickness from top to bottom. Over decades, careful thinning allows each tree to grow slowly, resulting in tight growth rings and a refined, beautiful grain.

Because branches naturally fall off or are pruned while still thin, the lumber is almost entirely knot-free. The wood from forest thinning in the Yoshino region is therefore a material of exceptionally high quality, distinct from thinned lumber from other regions. And it is from the remnants and offcuts of this superior thinned material that the celebrated “Yoshino Waribashi” are made.

The outer layer of cedar and cypress used for Yoshino chopsticks is pale in color, with a smooth and uniform grain that splits cleanly when snapped apart. Because of their fine annual rings, Yoshino cedar and cypress chopsticks have sufficient strength.

The Spirit of Using Every Last Piece

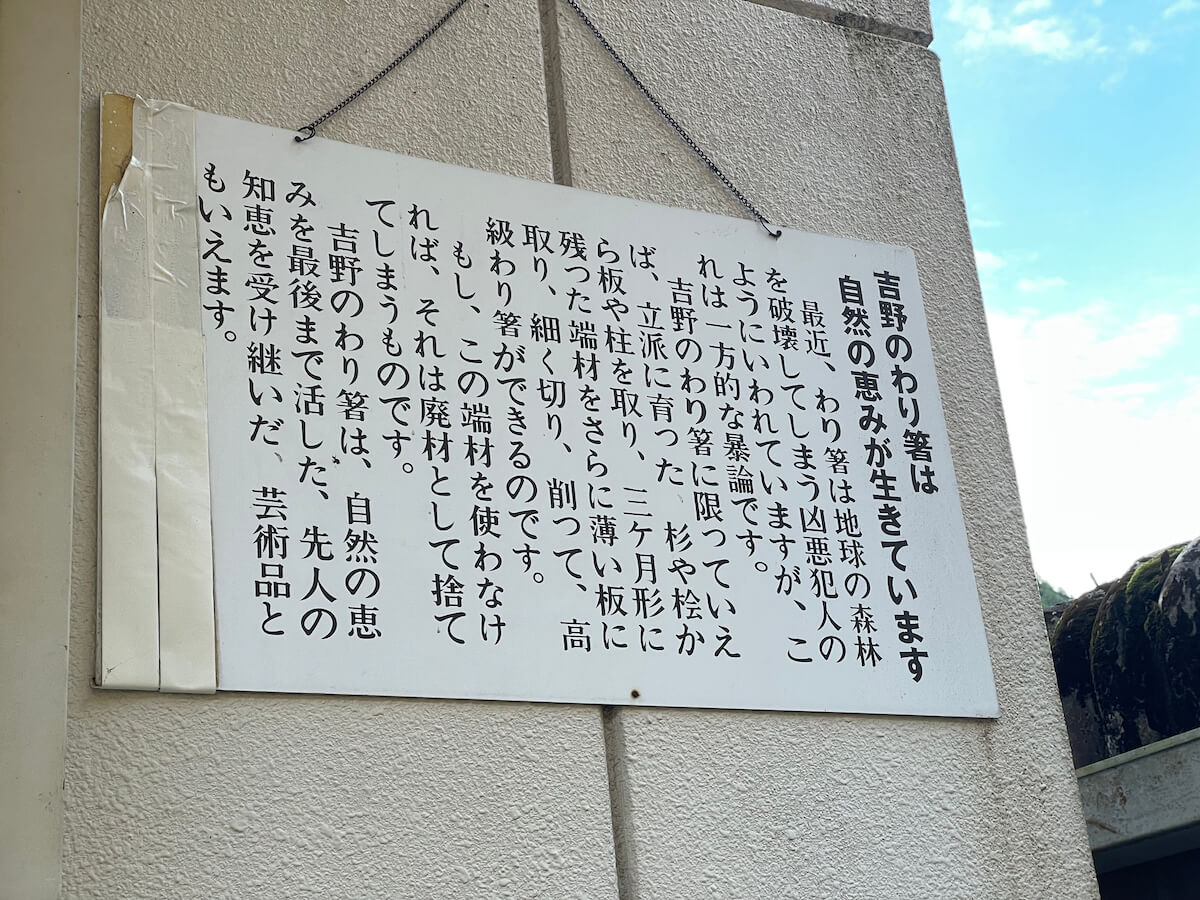

At the entrance of a chopstick factory in Yoshino, a signboard expresses the heart behind the craft (Kobayashi Yoshino Waribashi)

<Text on the signboard>

“Yoshino Waribashi carries the blessings of nature.

In recent years, disposable chopsticks have been criticized as destroyers of the world’s forests—but that’s a one-sided view.

In Yoshino, fine cedar and cypress are crafted into boards and beams, and the remaining offcuts are sliced thinner, trimmed, and shaved to make high-quality chopsticks.

If not used, these offcuts would simply become waste.

Yoshino Waribashi are works of art—a form of wisdom that carries forward the blessings of nature.”

How exactly is “Yoshino Waribashi” made?

The raw material used is called “Kowa”—the outermost offcut left after lumber is milled at the sawmill. Only flawless pieces without knots or decay will be selected. The wood is cut to length, soaked in water for 8–10 hours (or boiled for 3–5 hours in the case of cypress) to soften it, then shaped, chamfered, dried, and polished.

While modern machinery is certainly utilized, the process isn’t as simple as pushing a button and having the machine do all the work. In reality, crafting these disposable chopsticks requires multiple steps and a significant amount of time and effort. The final product is a testament to careful, multi-stage manufacturing.

Yoshino Waribashi Industrial Cooperative Association | YouTube

Yoshino Waribashi Industrial Cooperative Association | YouTube

Every finished chopstick is visually inspected by skilled workers and graded by hand. Only those that meet strict quality standards are shipped to market.

Yoshino Waribashi completed after many production steps

In Yoshino, even local elementary and junior high schools use those chopsticks for school lunches. Once the chopsticks have been used, they are not simply discarded. The used chopsticks are collected and sent to paper mills where they are actively utilized as a raw material for making new paper.

Because these trees have been carefully nurtured for decades, artisans believe it’s only right to use them fully—never wastefully. Using the lumbers from forest thinning means keeping the forest cycle healthy, too.

As one craftsman put it: “Don’t hesitate to use Yoshino chopsticks just because they’re high-quality—we want people to use them every day.”

Challenges: A Shortage of Successors and Declining Demand

Despite their sustainability, Yoshino’s waribashi industry faces serious challenges. The industry is facing a dual threat: the youth are moving to the cities, causing a succession crisis and an aging workforce. Simultaneously, a flood of cheap imported lumber is shrinking the market for domestic wood, leading to less available Yoshino timber and fewer of the offcuts needed for chopstick production.

A Small Step Toward a Sustainable Future

For us in Japan, chopsticks are part of the scenery—an essential, everyday tool. But disposable chopsticks? They offer a surprisingly easy way to pay attention to the planet.

“Yoshino Waribashi” is much more than just a product from a small town. They are a living culture, symbolizing the Yoshino region’s deep respect for wood and their firm belief in never letting anything go to waste.

This dedication to using wood completely is naturally kind to the global environment and perfectly aligns with the global mission of the SDGs.

Ready to make a sustainable choice? Start small: use “Yoshino Waribashi” today as your first step toward a sustainable society!

Information

Yoshino Waribashi Industrial Cooperative Association

100 Kuzu, Yoshino-cho, Yoshino-gun, Nara Prefecture 639-3434

Tel:0746-36-6838

URL:http://www.yoshinowaribashi.com/

Kobayashi Yoshino Waribashi

525 Natsumi, Yoshino-cho, Yoshino-gun, Nara Prefecture 639-3446

Tel:0746-32-1184

Takeuchi Waribashi

381-1 Minamiohno, Yoshino-cho, Yoshino-gun, Nara Prefecture 639-3437

Tel:0746-36-6823

Hirohashi Co., Ltd.

558 Shinjyu, Shimoichi-cho, Yoshino-gun, Nara Prefecture 638-0045

Tel:0747-52-1684

URL:https://yoroshiioagari.jp/

Text: Yoshino Kokubo

Edited by: “Nara no Ki no Koto” Editorial Team

Cooperation: Yoshino Waribashi Industrial Cooperative Association / Kobayashi Yoshino Waribashi / Takeuchi Waribashi / Hirohashi Co., Ltd.